The Importance of Selecting NZ-Made

Selecting NZ made products provides a level of assurance that suppliers who use offshore production are unable to fulfil. Additionally, the economic benefits are retained in New Zealand and fed back into local communities.

The core purpose of Passive Fire Protection (PFP) is to prevent loss of life and property by containing or minimising the spread of fire. PFP essentially protects the building and its inhabitants through ‘Safety in Design’. The major benefit is that PFP is effective regardless of the actions taken by individuals or active safety systems.

High density projects have been found to encourage stronger community relationships and interactions. Designing and developing these projects with this as a central point will help establish and enhance local communities, reduce urban sprawl, support public transport and unlock much needed housing supply.

Selecting local manufacturers not only provides designers and installers with innovative NZ made products designed specifically for the local market and building code, but also further supports our local communities.

Allproof manufactures PFP products at its factory on Auckland’s North Shore employing over 130 staff. As a New Zealand product manufacturer Allproof is an environmentally conscious business.

Selecting NZ made products provides a level of assurance that suppliers who use offshore production are unable to fulfil. Additionally, the economic benefits are retained in New Zealand and fed back into local communities.

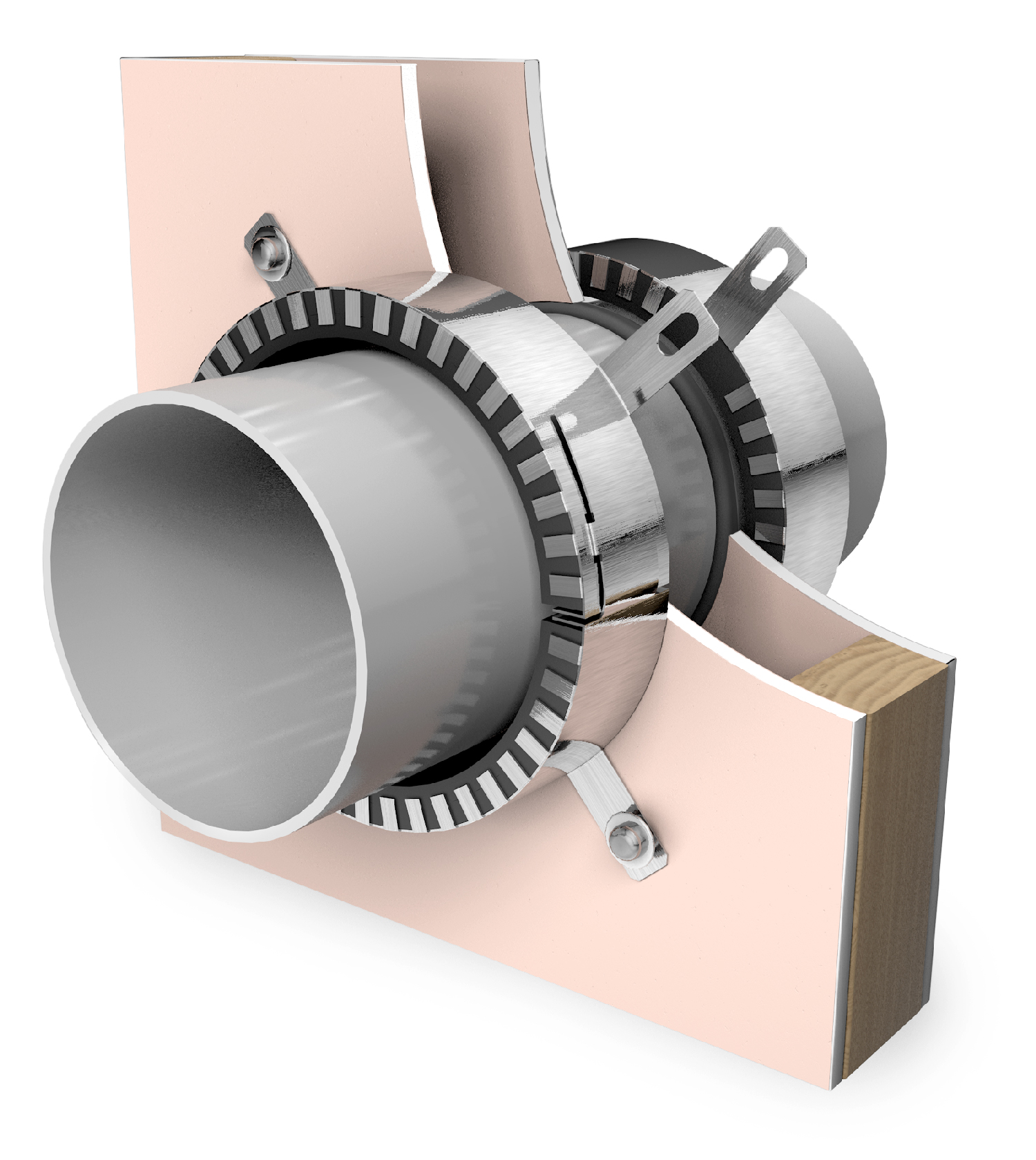

Allproof’s intumescent material is produced in-house, then cut and assembled into a range of products at the head office factory in Auckland. The cast-in fire collar range are moulded on site from 100% recycled materials using clean solar energy reducing the carbon footprint of innovative NZ made products.

All testing and assessments are conducted by independent accredited testing laboratories. Further to this, Allproof’s PFP range and literature has been BRANZ Appraised ensuring integrity and providing utmost assurance in selection, performance and installation.

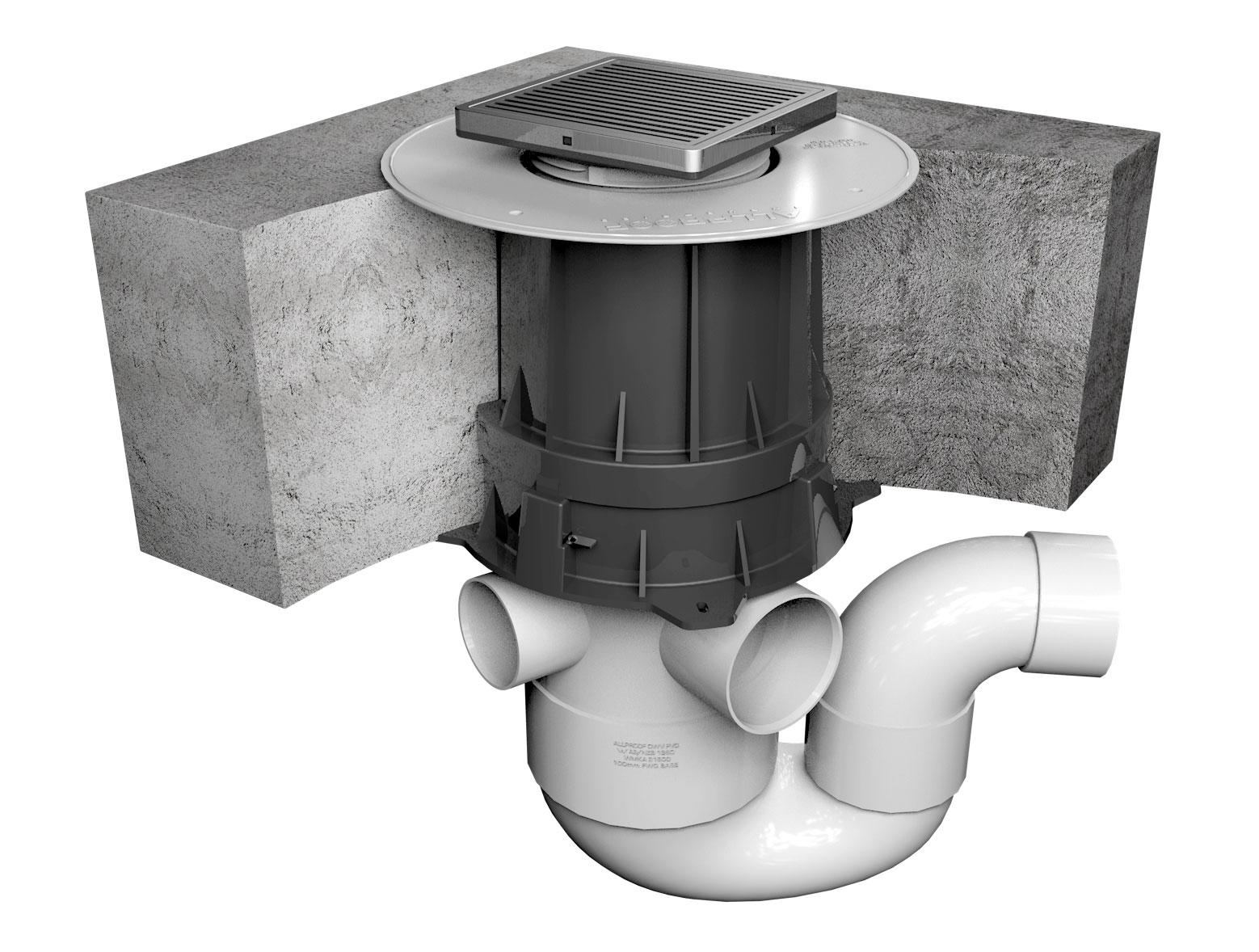

Drawing upon experience as a plumbing and drainage manufacturer Allproof are perfectly positioned to design and develop new products specifically catering to the local NZ industry. When composite steel tray floors with undulating profiles were introduced to New Zealand, Allproof were able to respond to demand as the innovator of the drop in fire collar system. This provides an excellent example of how local manufacturers can respond to industry developments using Kiwi ingenuity combined with advanced production facilities.

Allproof distribute PFP products through a nationwide network of merchants which ensures accessibility to the products. Allproof’s technical team support and train installers through its national sales network, offering a range of solutions for PFP with specialist knowledge on its integration with other plumbing and drainage systems.

Selecting Allproof provides a premium PFP solution while supporting local NZ manufacturing.

Read More

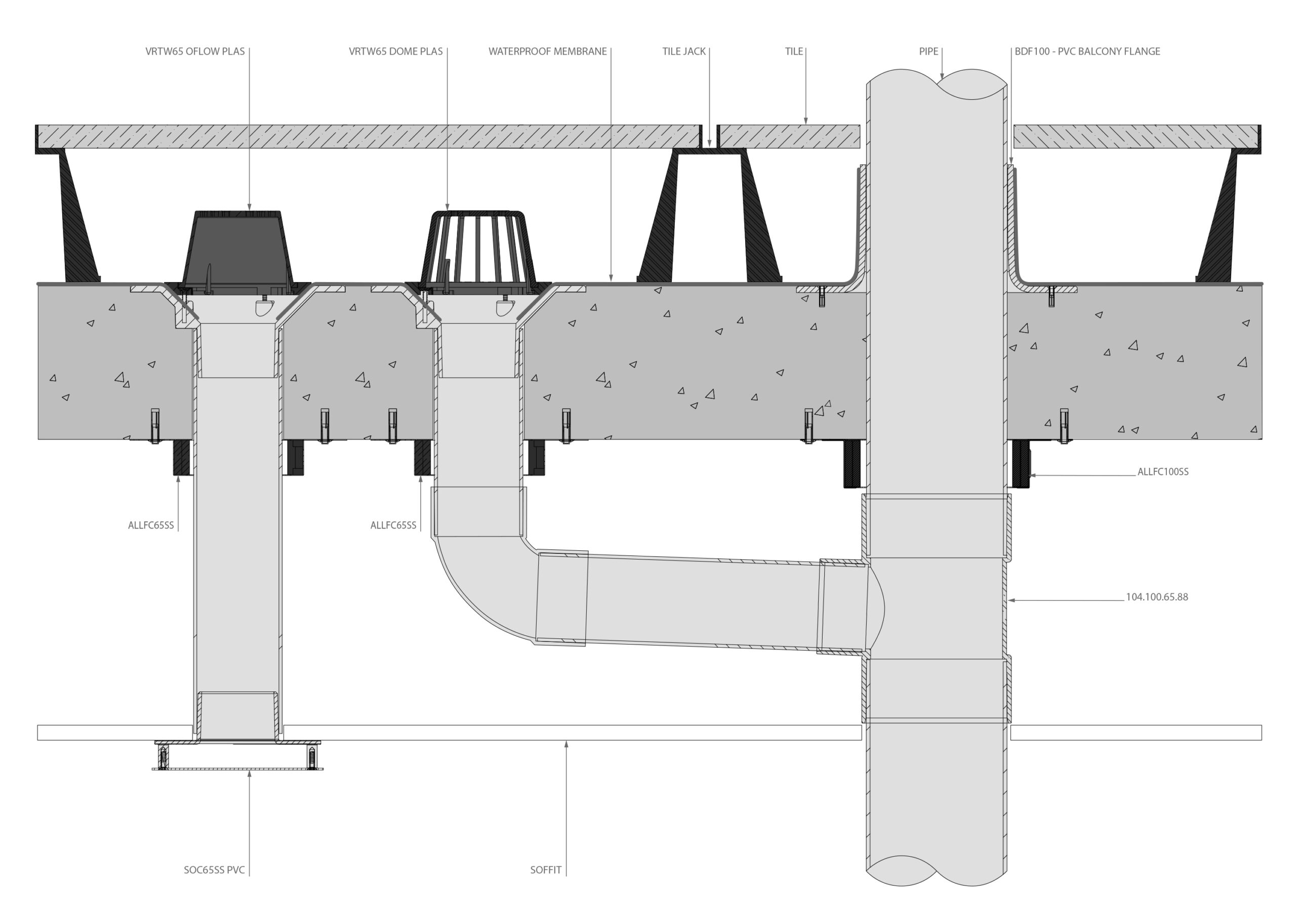

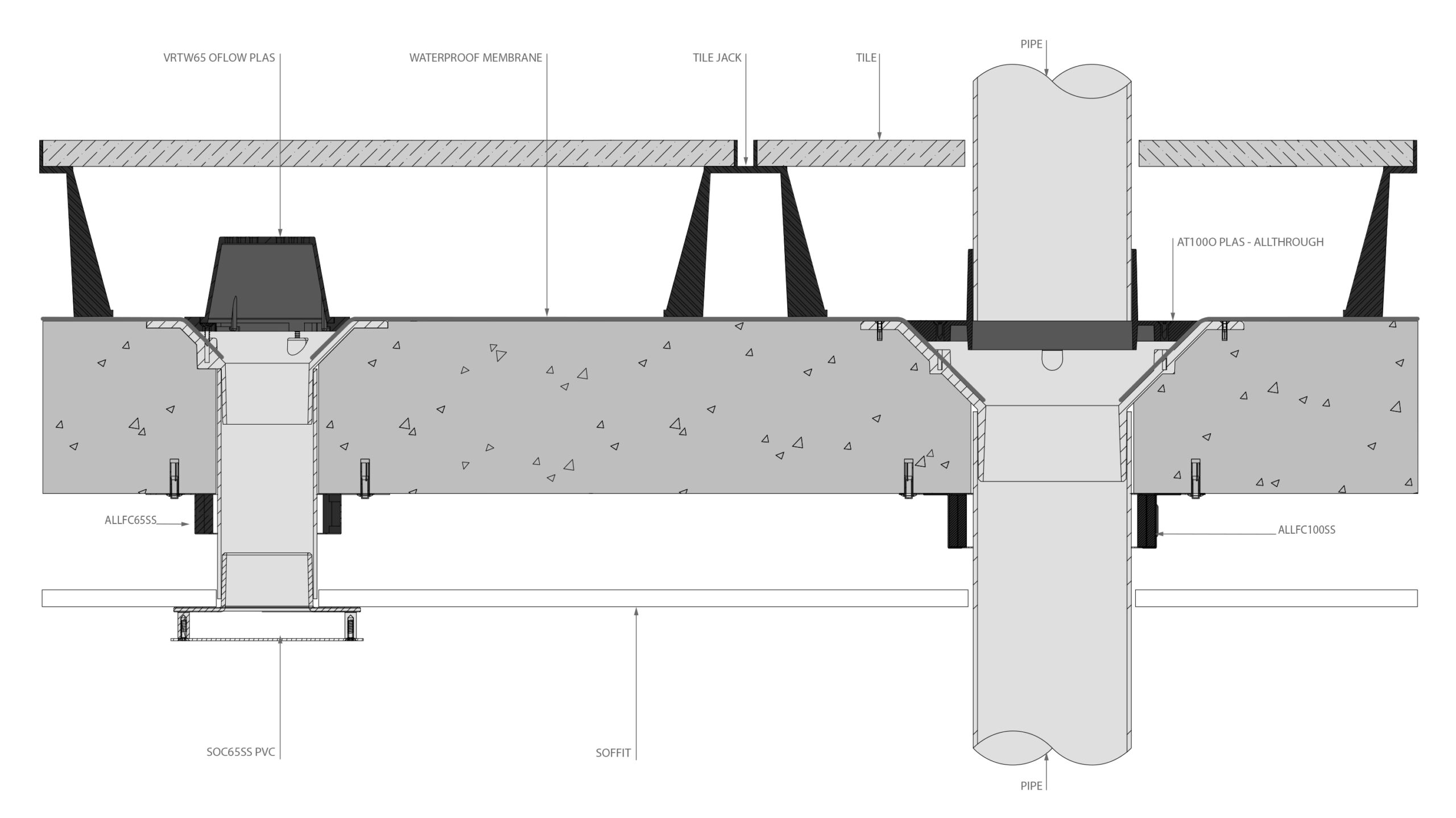

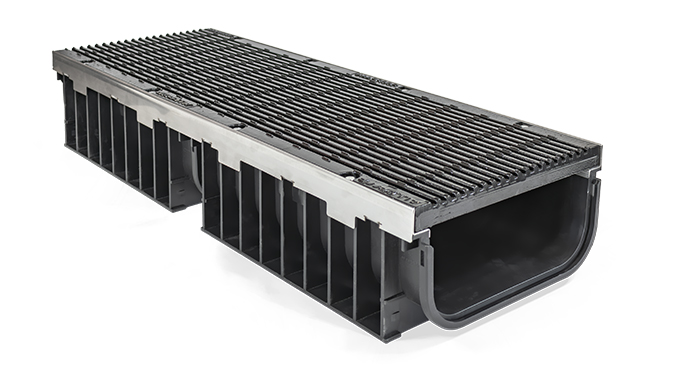

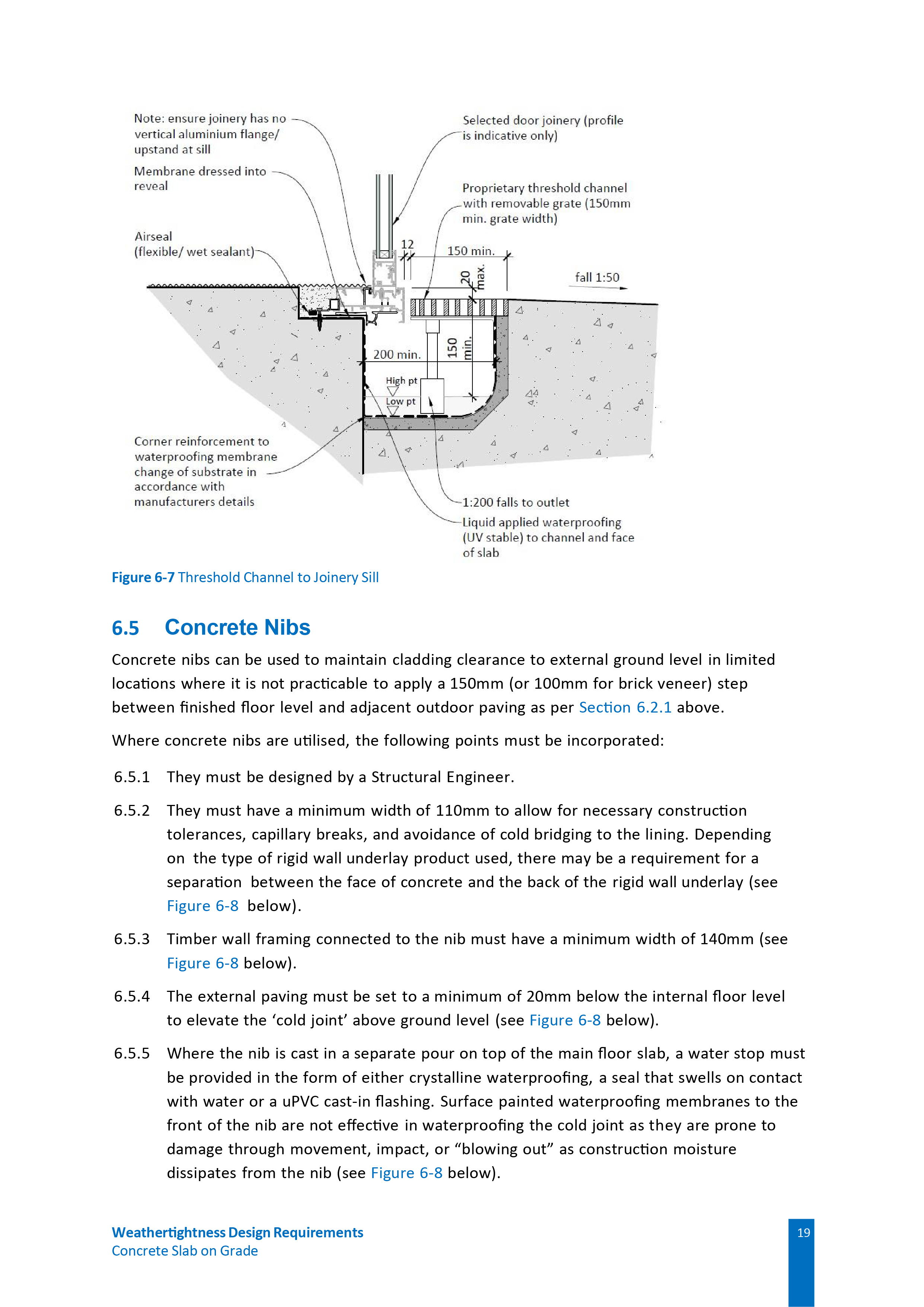

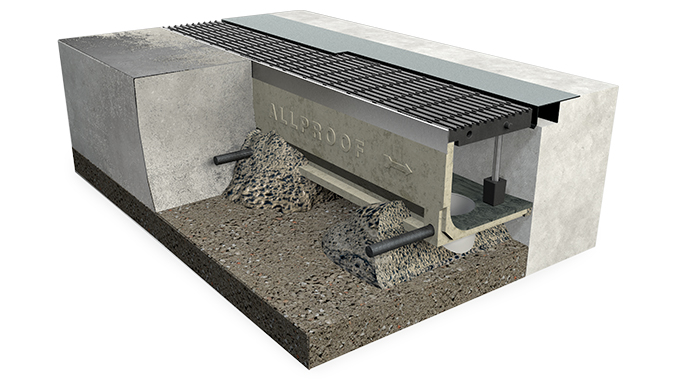

The channel itself is designed to be installed against the building slab running parallel to the joinery line. When installed following Allproof documentation the channel provides a 200mm wide x 180mm reveal against the building foundations, this reduces labour-intensive boxing out, multiple concrete pours and post-installing fixings to provide support to the system. The preformed L-shaped channel allows a waterproof membrane to be easily dressed from the building slab down into the channel. The 180mm depth allows for a 1:200 fall to be screeded into the base maintaining compliance with all NZBC E2 and MoE design standards. To ensure the 150mm grate width the channel can be set back off the building foundations, increasing the internal width of the channel. This would be applicable if the joinery extends over the channel reveal by more than 38mm (accounting for the continuous gap of 12 mm).

The channel itself is designed to be installed against the building slab running parallel to the joinery line. When installed following Allproof documentation the channel provides a 200mm wide x 180mm reveal against the building foundations, this reduces labour-intensive boxing out, multiple concrete pours and post-installing fixings to provide support to the system. The preformed L-shaped channel allows a waterproof membrane to be easily dressed from the building slab down into the channel. The 180mm depth allows for a 1:200 fall to be screeded into the base maintaining compliance with all NZBC E2 and MoE design standards. To ensure the 150mm grate width the channel can be set back off the building foundations, increasing the internal width of the channel. This would be applicable if the joinery extends over the channel reveal by more than 38mm (accounting for the continuous gap of 12 mm).

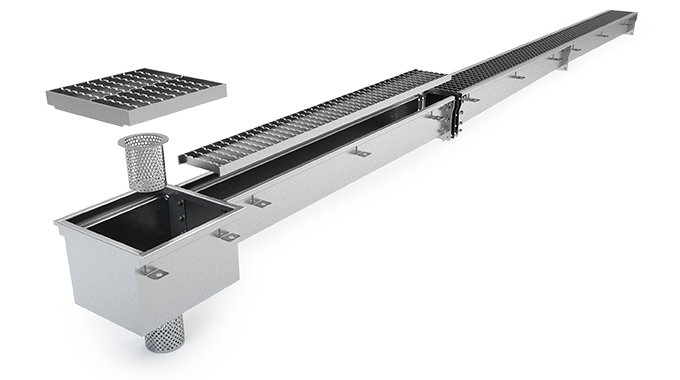

Allproof’s commercial kitchen channel (

Allproof’s commercial kitchen channel (