Deconstructing Passive Fire Protection Systems

The recent unfortunate events in Wellington, bring back into focus the elements involved in multi-storey buildings regarding fire safety, whether they are active or passive fire protection (PFP) systems within the building envelope. The building’s systems need to work hand in hand and function appropriately in the event of a fire-related emergency.

Ultimately, the building design in relation to the fire compartments and cells is geared towards containment, as well as creating safe paths out of the building and affected areas.

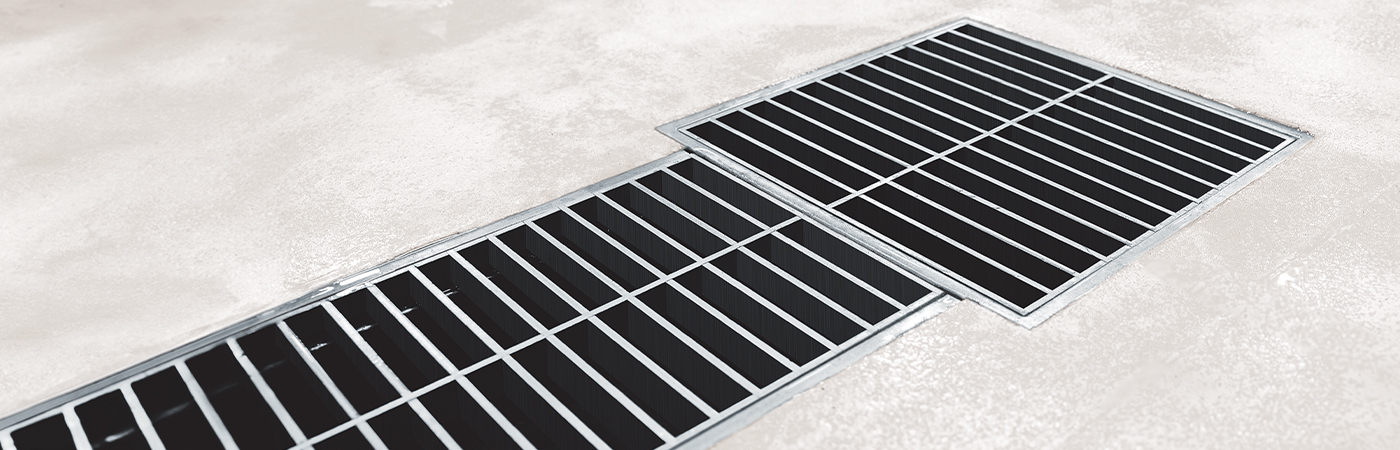

Walls, floors and ceilings are examples of building elements that are used as part of a fire separation system that forms fire compartments that inhibit the spread of fire vertically, or horizontally. These elements are commonly penetrated by service entries into and through the zones for the buildings utilities and need to be protected by a passive fire protection solution.

What is an FRL?

The building’s Fire Resistance Level (FRL) is determined by a fire engineer and is based on the activities, age and mobility of the occupants along with the building’s design, size and proximity to other properties or structures. The design of the fire protection system provides sufficient time for building occupants to safely evacuate and allows firefighting and emergency services to control the fire, limiting further spread.

The building’s construction methods and the services within the building envelope introduce elements that need to be treated as part of the PFP system. Individual service penetrations demand a designed and tested fire-stopping solution with an associated FRL to meet the requirements of the building’s fire protection performance criteria.

What happens in the event of a fire?

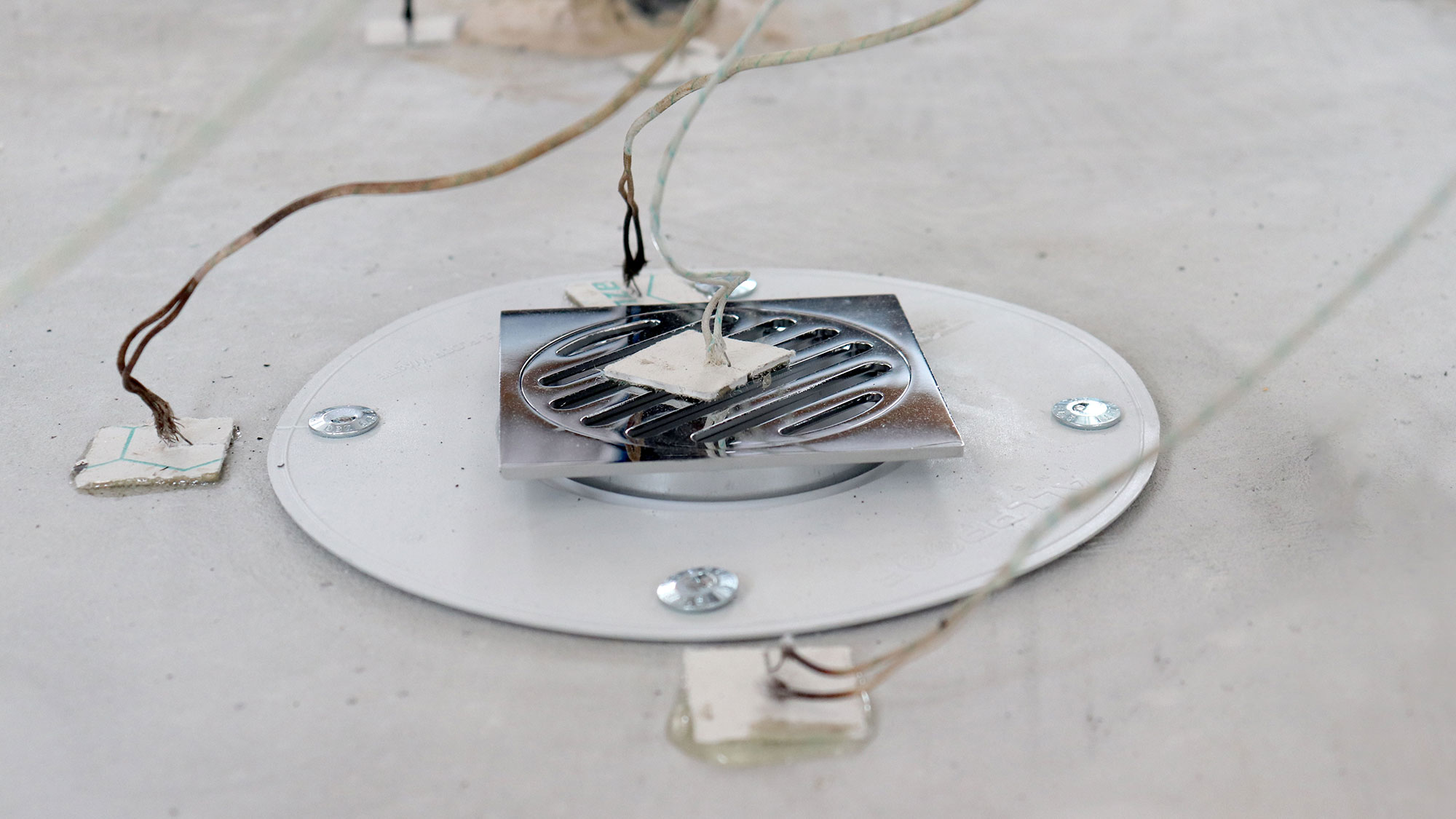

In the event of a fire, the intumescent material in the PFP device activates when the installation is exposed to heat which in turn causes the volume to increase at a significant rate and pressure. The service material (e.g. PVC pipe) melts away and the expanding intumescent packs the void creating a char, which fills the space left by the service. The activated intumescent is a poor thermal conductor which retards heat transfer and insulates the penetration preventing the fire from spreading between areas.

Testing and product selection, ‘the system’

An example of an Allproof Industries PFP system, is a Stainless-Steel Shower tray, Trayrite outlet, Floor waste Gully and a Low-profile Fire Collar installed on a concrete flat slab or rib and timber infill constructed floor. This system has been independently tested to provide an Integrity and Insulation FRL result for the specific penetration, which can be incorporated into the building’s overall FRL and therefore protect the area above the associated service penetration. Other floor construction methods such as Composite Floors, as well as, rib and timber infill, also have a tested shower system solution using a Drop-in Fire Collar as the passive fire protection device. The Drop-in Fire Collar, designed by Allproof, allows the service penetration to be cored out on any profile of the flooring tray and easily achieves the required FRL without the use of batts or creating plaster surrounds.

Allproof Industries is an NZ manufacturer and leader in the passive fire protection market. Coupled with their NZ-made plumbing and drainage products, they provide an innovative range of passive fire protection systems and solutions to offer.

Service penetration passive fire protection is critical to the overall integrity of a fire cell and can contribute to a positive outcome in the event of a fire if correctly installed to specification.

The passive fire protection industry has come a long way in the last couple of years. We should all collectively strive to cause change and learn from events, by ensuring our designs and solutions contribute to reducing harm and damage caused by a fire. Partnering with a reputable local manufacturer is the first step towards this goal.