Allproof are at the forefront of industry leading level threshold systems by developing innovative design solutions that have been selected for high profile projects such as Commercial Bay, Kings School in Remuera and Hillmorton Hospital.

Located on the North Shore of Auckland, Allproof’s team of over 130 staff include tradespeople such as engineers, fabricators and product designers. As a New Zealand product manufacturer Allproof is perfectly positioned to develop products that drive the NZ construction industry forwards through innovative systems designed specifically to the NZBC and local trade practices.

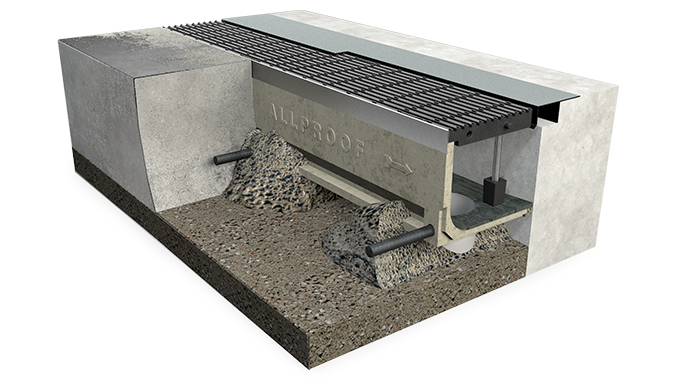

The latest development by Allproof is a design update to the Perimeter Drain. Since its initial launch in 2016 the Perimeter Drain has transformed the level threshold drainage market in New Zealand. Through a regular R&D program the Perimeter Drain has been recently reviewed to consider design efficiencies from materials to installation process.

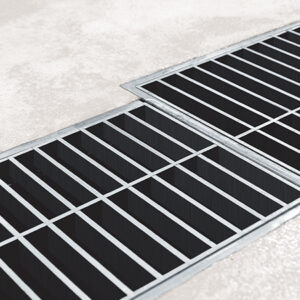

The design update has removed the bracket system from the polymer (GFP) and stainless grates, a clip is attached to the pre-installed fixing points on the channel wall allowing the grates to simply ‘clip’ into place.

The new grate and clip system is NZ made using recycled material and reinforced with glass fibres and UV protection. This provides an environmentally conscious and highly durable solution for level threshold installations.

The L shaped channel is installed as usual to create a 180mm x 200mm reveal against the building foundations, this reduces labour intensive boxing out and multiple concrete pours. The 180mm depth allows for a 1:200 fall to be screeded into the base maintaining compliance with NZBC E2.

Clips are then fastened to the channel wall at the pre-installed fixing points.

Off the shelf polymer grates are trimmed on site to suit the reveal while allowing for a 12mm separation along the joinery line, alternatively a custom stainless-steel grate can be fabricated to accommodate. Nuts are either inserted into the underside of the polymer grate, or supplied attached if a stainless grate has been selected. The threaded legs are screwed on, and height adjusted via the foot to suit the channel depth before being clipped into place.

This significant update provides a premium finish through easy on-site customisation when using the GFP grate, therefore removing delays and hold ups towards the end of a project. This improves the transition between trades and contributes to delivering the entire project on schedule.

Allproof are confident this innovative design update marks a significant evolutionary step in NZ made level threshold systems that will improve the installation process while providing a superior finish.