Premium Drainage Solution for Chip Production Facility

One of New Zealand’s leading snack brands have spent 150 years building a strong reputation as a quality food manufacturer. Their potato chips have been an integral part of their success as a market leading brand with a large range of products on supermarket shelves across NZ.

As a result of this success, its production facility has been expanded to increase capacity and efficiency. The new facility was designed by Designgroup Architects h + k and completed in 2020. It currently processes an average of 400 tonnes of potatoes per week, equating to approximately 720,000 packets of chips per week.

The equipment used at the Auckland facility is industry-leading. This includes automated machinery along large production lines, where the processing stages are separated into defined locations so that the infrastructure in the areas can cater to the requirements of each stage.

The separating, washing, and cooking stages presented unique challenges that the design team had to address. During these stages, large volumes of water and other liquids are used. The building needed to be designed to cater to daily operations and weekly boil-outs/deep cleans but also withstand significant dumps of water to keep floors clear of hazards should they occur. The facility also recycles wastewater from the production cleaning process to be reused, adding another layer of consideration for drainage, as other facilities interact with the overall system.

The drainage systems around the large and high-tech equipment needed to be designed to work efficiently through all the anticipated scenarios that could be foreseen, as well as provide a robust, durable, and hygienic solution.

Allproof Industries, a specialist in commercial food and beverage production facility drainage, was engaged to assist in the design and manufacturing of a system that would meet the operational requirements over the lifetime of the facility. Allproof worked closely with the design team to create the optimal drainage solution for the challenges faced. Drainage systems are built into the floor slab to suit the layout and operation of the production facility. It is imperative that the system is designed to fulfill all the requirements, as it can be costly to remedy if it does not perform as needed.

A good drainage system contributes to food safety, hygiene, and cost control — all vital factors in a successful commercial food operation.

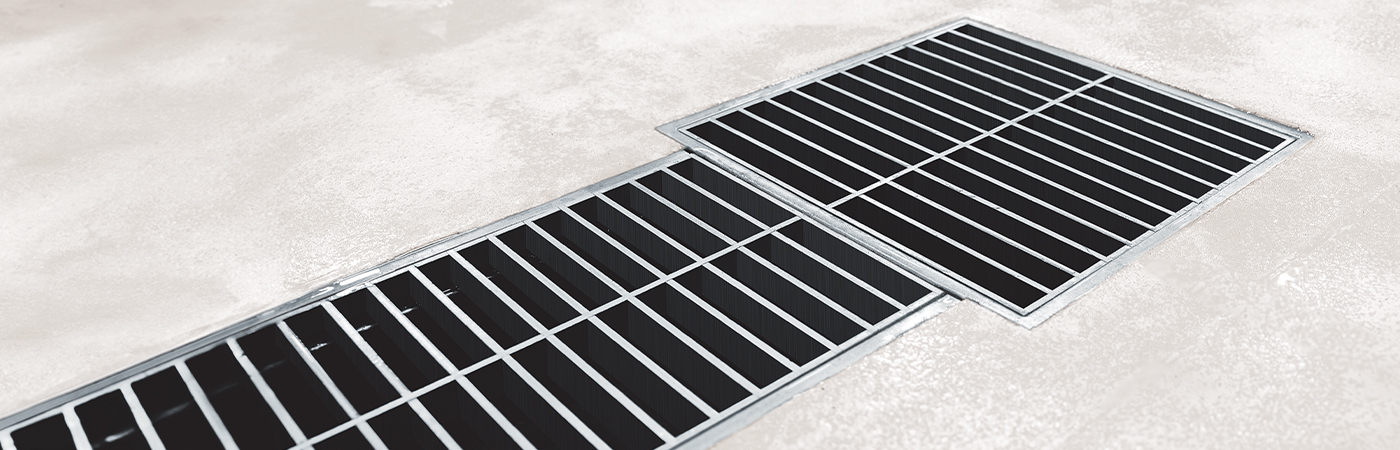

The ladder grate with a load class C rating (AS3996) was selected, as large machinery will often pass over drainage systems due to the nature of the facility being a production factory. Furthermore, the ladder grate openings are large, which improves hydraulic performance and can remove solids (potatoes) from the floor surface, catching them in the sump’s strainer basket, reducing trip hazards.

Channel depth is a factor in wastewater catchment and hydraulics. The channels were selected/designed to provide enough capacity to capture the surface wastewater, so as not to cause flooding or safety hazards. Each channel section terminates at a sump, and an outlet performs better hydraulically if there is a head of water creating pressure. This increases the flow rate and, thus, the speed at which wastewater is removed from the drainage channel system. Therefore, the depth of the sump was created to a requested measurement, as determined by the hydraulic design.

The drainage system is made from stainless steel as it makes an excellent hygienic material for food processing facilities. It contains no pores, cracks, or open spaces for bacteria, including odour, to embed itself in, as it is a self-contained piece of material. Its great mechanical properties mean it’s also resistant to dents and surface defects, ensuring the surface remains sealed for hygienic purposes. It is also easy to maintain/clean, ensuring that bacteria don’t have an opportunity to grow or spread.

Overall, Allproof manufactured and supplied 69 meters of stainless-steel channel drain with 22 sumps, either connected to or separate from the channel drain system. This provides an excellent case study of a food manufacturer looking for specialized expertise.

By using other local knowledge and manufacturers the potato chip brand ensured the success of their project positioning them to meet growing demand in their own product offering.