Five Factors to Consider When Specifying Stormwater Drainage Systems

The primary objective of AS/NZS standards is to safeguard people from injury or illness, and property from damage. There are many elements which contribute towards this objective. Outlined are five key factors to consider when selecting the appropriate products for the job.

Application

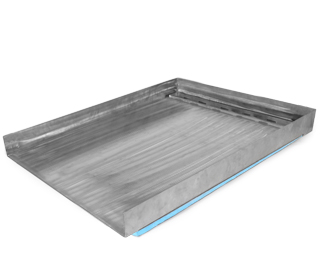

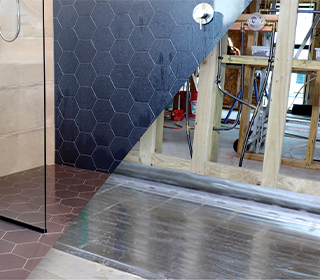

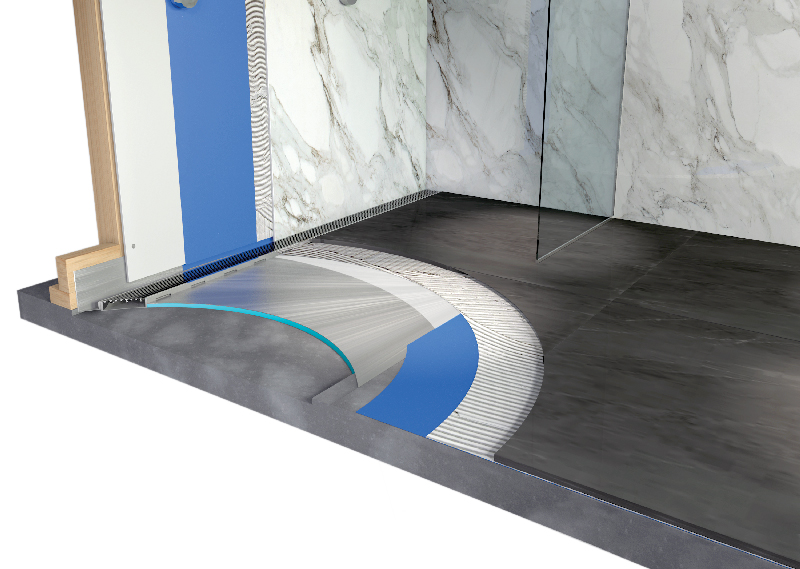

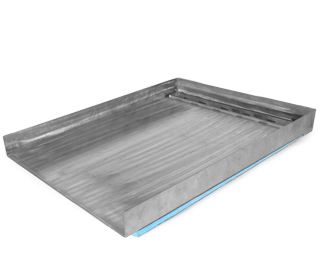

Ensure you select the correct type of product for the job. Is a channel required or will a sump suffice? Is this a level entry into a habitable space, a channel drain in front of a drive/garage, or a collection point before going into the local authorities’ stormwater system? Each application has different requirements set out in NZBC and applicable AS/NZ Standards. A level entry scenario requires a 200 x 150mm channel and a 12mm drip line along the joinery (plus other various details), therefore a standard three sided channel is not applicable in this application. Each drainage system has been designed for a specific application, if you are unsure it is worth discussing your project with the channel supplier to avoid costly delays and work by removing a system that isn’t compliant.

Performance

Performance

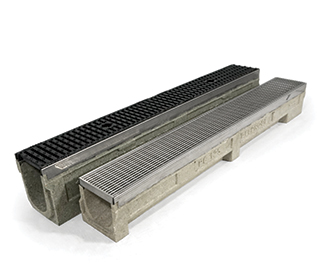

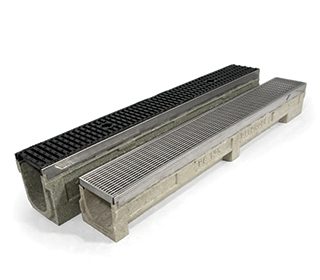

Ensure that the selected drainage product’s hydraulic performance meets the needs of the application. This may be a combination of the channel depth/width and grate open area or even just how the product is set up. Understanding the topography of the area will also have a large part to play, installing a slot drain with a 15mm opening at the bottom of a steep drive means that during a heavy downpour surface stormwater will likely bridge the gap and the drain will not perform to the desired level, however, a wider grate with more open area (eg. Allproof PC with cast iron grate) would allow the water to drain. A channel slot drain would work well in a courtyard with a fall towards it from both sides. It is best practice to seek advice from a specialist hydraulic consultant in this area.

Load Rating

AS3996:2019 Access Covers and Grates outlines the requirements for grate load class ratings. Grates must perform well under subjected loads appropriate to their application once installed. The standard provides a rating of A to G with A being “areas (including footways) accessible only to pedestrians and pedal cyclists and closed to other traffic (extra-light duty)” with a nominal wheel load of 330kg, and G for “docks and aircraft pavements subject to very high wheel loads (extra heavy duty)” with a nominal wheel load of 30,000kg. The majority of applications will require a load rating between A and D which would cover commercial vehicles in areas such as loading bays. Allproof have developed in-house testing to ensure their products meet the specifications laid out by AS3996, this information is available in their literature to aid product selection.

Environment

The environment plays a large factor in material selection when choosing a product. Stormwater drainage products are exposed to large amounts of moisture by nature of the application. It is important to understand the chemical and physical characteristics of materials in each environment. Cast iron is an excellent material for strength with a long life expectancy and economic price point, and its bituminous paint coating does provide a degree of protection from the elements. However, unless regularly re-painted it will wear off exposing the cast iron and oxidation will naturally occur.

Depending on the environment this can remain for some time, in high trafficable areas it will pass quicker and will eventually stabilise into a dull dark brown patina. This is a natural material reaction to the environment, it’s aesthetic and does not impact performance. In some scenarios (laneways) this may be a desired aesthetic, but the lifetime appearance should be considered in projects where a consistent appearance is desired. Allproof recommends high grade 316 stainless steel in marine environments as it has a higher degree of resistance to corrosion and reduces the need for regular maintenance, alternatively glass filled nylon (GFN) provides a black finish that doesn’t react to the environment.

Grating Design

Grating Design

Considerations additional to the features discussed above include the grating open area. Open areas will affect the hydraulic performance of the system, larger open areas would generally perform better hydraulically, smaller individual open areas may be more prone to blocking from debris. However, smaller individual open areas would be advisable in pedestrian zones, Allproof have classified a range of their grates as heelproof for use in areas likely to see high levels of foot traffic. Heelproof grates are designed to resist entry of high-heeled shoes by limiting the smallest dimension for an opening to 8mm or less.

It is also advisable to consider slip resistance on grate surfaces. This can be important in settings likely to be subjected to high volumes of foot traffic for example, busy urban streets and commercial courtyards. AS 4586:2013 covers the requirements and classifications for slip resistance, a variety of Allproof grates have been tested by an independent laboratory with excellent results ranging from R9 to R13.

Read More