1. Compliance with NZ regulations

The New Zealand Building Code (NZBC) ensures Kiwis have the highest standards of health, hygiene and safety in their properties, taking into account New Zealand’s unique weather and climate conditions and user requirements. For waste and drainage systems, the objective of NZBC Clauses E2 External Moisture and G13 Foul Water is:

-

- E2.1 to safeguard people from illness or injury that could result from external moisture entering the building

- G13.1 to:

- (a) Safeguard people from illness due to infection or contamination resulting from personal hygiene activities; and

- (b) Safeguard people from loss of amenity due to the presence of unpleasant odours or the accumulation of offensive matter resulting from foul water disposal.

Through their accompanying compliance documents, both clauses set out expectations for the design, construction and installation of waste and drainage systems to protect buildings and occupants.

These, together with relevant AS/NZS Standards, are the main resources for the design and development of drainage products here in New Zealand, ensuring NZ based manufacturers are well-positioned to supply the local market with products specifically for New Zealand’s construction industry.

2. Local knowledge for product development

Allproof draws on insights and knowledge gained through the company’s 33-year heritage of partnerships and collaborations with top New Zealand plumbers, hydraulic engineers, architects and industry bodies, such as Master Plumbers.

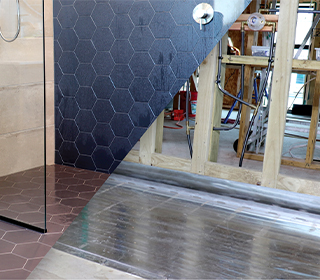

By utilising these relationships, Allproof has been able to grow and maintain a large product portfolio based on the critical feedback and insights from the New Zealand construction and plumbing community. Products such as the Tile Over Stainless Tray have eliminated the need to screed a fall into the tray hence reducing work needed on site to install. Once again this process was all possible thanks to the product feedback from the construction and plumbing industry.

With a New Zealand-based team of over 100 tradespeople, machine operators, engineers and operations staff, Allproof’s ongoing product development programme is well equipped to implement the feedback creating innovative systems for the plumbing and drainage industry in a fast-paced and challenging climate.

This process means products have been developed with the installer in mind and the unique challenges of the New Zealand building design and construction industry they face on-site every day.

Tile Over Stainless Tray

3. Investment in manufacturing processes

New Zealand’s plumbers and drainlayers want systems that perform to the highest standards and stand the test of time. Knowing that continuing investment is being made into production processes and controls gives installers confidence that products are fit for purpose in the work they are completing (reflecting back on the core objectives of the NZBC and AS/NZ Standards).

Allproof consistently invests in their manufacturing processes to control all aspects of product production and to maintain a high level of quality across the range. Engineers maintain and develop moulds in the company’s fleet of injection moulding machines, whilst a department of 30 fabricators use some of the industry’s most advanced technology to ensure accuracy and quality in Allproof’s stainless steel drainage products.

4. Accessible technical advice and assistance

Easy, first-hand access to product advice and assistance is another key advantage to using NZ made. With an in-depth understanding of the applicable Building Code clauses and Standards, Allproof’s NZ based sales team of eight are able to provide in-depth technical insights and advice for the application of the company’s drainage and waste products.

The team has a range of skills and backgrounds, including plumbers, builders and staff who have been with the company for over 12 years. The sales team help designers select and design drainage systems specific to projects, visit sites to provide technical information and installation training and to assist with measurements where possible.

5. In-house design for customised systems

Commercial projects often have unique requirements that benefit from purpose-designed drainage systems. Drawing on industry and technical knowledge, Allproof’s in-house design team are able to design drainage systems that cater for project-specific scenarios. This full in-house design service is unique to Allproof and allows the company to supply custom-designed systems with high drainage performance that cater to each site’s limitations and install requirements. Allproof has been at the forefront of the shower channel product design with our custom stainless steel Vision Shower Channel, utilising linear drain options we are able to customise the channel length for project specific jobs.

The stainless steel fabrication department then manufactures these systems to the highest level of accuracy and, before being dispatched, all products must pass a Quality Assurance process from a QA dedicated team member.