Achieving MoE Design Standards for Level Threshold

The Weathertightness Design Standards for School Buildings by the Ministry of Education (MoE) is a comprehensive guide aimed at architects and designers for creating educational facilities that are safe, healthy and durable with lifetime cost economics in mind.

Within the document, the MoE advises on best practice for creating level threshold transitions to protect internal spaces at building entrances. Advice covers a range of considerations from where to position accessible entrances to the design specifics of the channel and grating system.

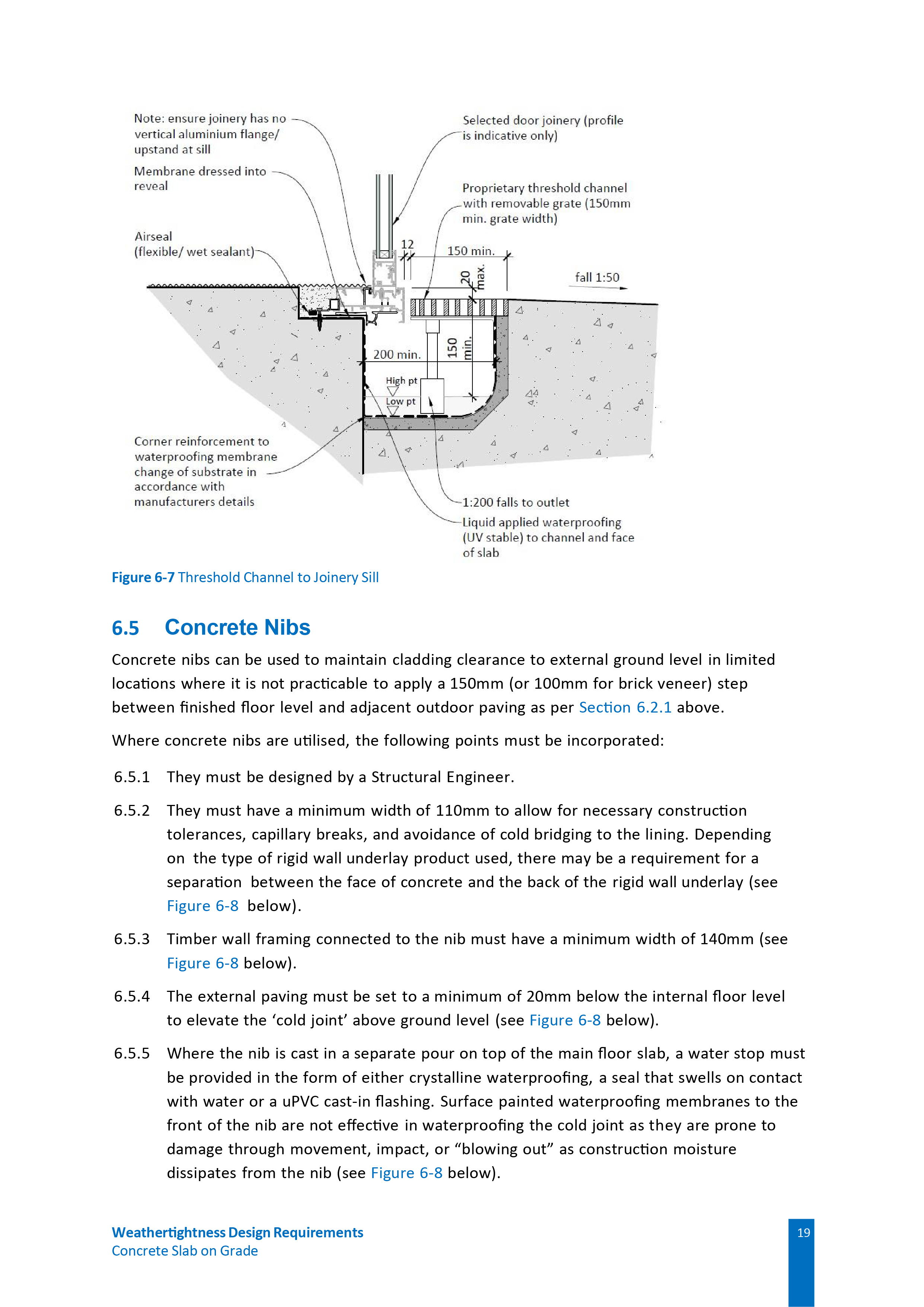

Regarding the design of the channel itself, the standards identify the following criteria.

- Designed to be dry in service with a 1:50 fall away from the channel (not towards it),

- Minimum 200mm width x 150mm depth internal channel dimensions,

- Minimum grate width of 150mm,

- Outlets at a maximum of 3,700mm centres or 7,400mm centres if sufficient shelter is provided,

- Grate design to be easily removable for school staff to conduct maintenance, and should consider prevention of removal or vandalism by others,

- Maximum of 20mm surface level change between grate and internal surface to meet NZBC and NZS4121 accessibility requirements,

- The foundation & slab edge must be waterproofed with a liquid-applied UV-stable membrane,

- Channels laid to create a minimum of 1:200 falls to a sump connected to the stormwater system,

The design is to also consider NZBC Clause E2 which includes the following criteria:

- is supported independently of the door frame,

- is specifically designed to accommodate imposed loads,

- has gaps sized to prevent the wheels of wheelchairs or mobility aids from entering or being trapped, and

- has a continuous gap of 12 mm minimum from the door frame and wall cladding.

The MoE weathertightness standards make an important clarification on the use of three-sided channels as alternative solutions:

“6.4.10 Three-sided pre-formed channel systems are prohibited – the required solution are systems specifically designed for level thresholds to building perimeters, of which there are a number available in the market.”

The document illustrations appear to take reference from Allproof products with the profile of the Perimeter Drain channel shown in the details. The Allproof Perimeter Drain has recently undergone a significant design update enhancing features that the MoE weathertightness standards outline.

The channel itself is designed to be installed against the building slab running parallel to the joinery line. When installed following Allproof documentation the channel provides a 200mm wide x 180mm reveal against the building foundations, this reduces labour-intensive boxing out, multiple concrete pours and post-installing fixings to provide support to the system. The preformed L-shaped channel allows a waterproof membrane to be easily dressed from the building slab down into the channel. The 180mm depth allows for a 1:200 fall to be screeded into the base maintaining compliance with all NZBC E2 and MoE design standards. To ensure the 150mm grate width the channel can be set back off the building foundations, increasing the internal width of the channel. This would be applicable if the joinery extends over the channel reveal by more than 38mm (accounting for the continuous gap of 12 mm).

The channel itself is designed to be installed against the building slab running parallel to the joinery line. When installed following Allproof documentation the channel provides a 200mm wide x 180mm reveal against the building foundations, this reduces labour-intensive boxing out, multiple concrete pours and post-installing fixings to provide support to the system. The preformed L-shaped channel allows a waterproof membrane to be easily dressed from the building slab down into the channel. The 180mm depth allows for a 1:200 fall to be screeded into the base maintaining compliance with all NZBC E2 and MoE design standards. To ensure the 150mm grate width the channel can be set back off the building foundations, increasing the internal width of the channel. This would be applicable if the joinery extends over the channel reveal by more than 38mm (accounting for the continuous gap of 12 mm).

The stock grate is designed to allow for trimming down on site at regular set widths, this means that the grate width can be customised to maintain and not exceed the 12mm continuous separation from joinery. Inspectors may disapprove of larger openings that present a trip hazard, debris to enter or hands to get caught in.

The Perimeter Drain design update means that grates are now secured in place using an innovative clip system. The clip itself is attached to the channel wall using pre-installed fixing points. The Glass Filled Polymer (GFP) grate, NZ made from recycled materials and solar energy, is available off the shelf, it can be customised on site to suit the channel reveal dimensions.

To clip the grate into place and remove it a flat-head screwdriver is needed to lever the clip back, this ensures it is easily accessible for maintenance staff while also tamperproof for young students.

The stainless options are fabricated by Allproof to suit the channels and maintain the 12mm separation from joinery once installed.

Allproof’s Perimeter Drain system has been designed to suit load class A – pedestrian traffic. Grates have been designed to have perforations that provide excellent hydraulic performance while preventing wheels or other walking aids from becoming caught. The grates are designed with NZBC Clause D1 accessibility in mind with testing for slip resistance up to an R11 classification and going further with design features such as Heelproof grate openings, also helpful for keeping things like fingers out.

The Perimeter Drain update provides a premium finish through easy on-site customisation when using the GFP grate, therefore removing delays and hold-ups towards the end of a project. This improves the transition between trades and contributes to delivering the entire project on schedule.

Allproof’s level threshold solutions have been used across New Zealand in educational facilities such as Kings School Remuera, Rolleston College, Scott Point School, Massey University, AUT Auckland CBD campus and Long Bay College just to name a few.

Allproof is confident the innovative Perimeter Drain update marks a significant evolutionary step in NZ-made level threshold systems that meet the requirements of the MoE while improving the installation process and economy, and providing a superior finish.

PERIMETER DRAIN

The Perimeter Drain presents an innovative and premium solution for simplifying level threshold drainage.