A short guide to designing an external surface water drainage system that protects your dwelling from moisture while maintaining visual consistency and high performance.

A typical residential project will likely require various surface water drainage systems installed at the property entrances and at the property boundary to protect the building from moisture and mitigate runoff into the street. Each scenario will have different requirements based on its performance needs and applicable building codes. The following describes typical scenarios you may face and how these systems would converge before surface water can be drained into the local authorities stormwater system.

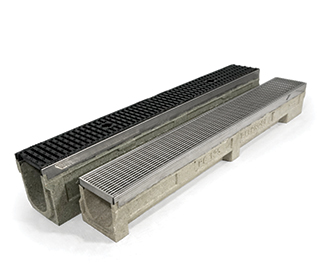

Garage and Driveway Drain

For attached garages (areas not deemed to be habited spaces) the door openings will have a “50 mm minimum total level change between the interior and the exterior paving” (E2/AS1 clause 9.1.3.4) in the way of a nib and/or ramp, a drainage channel would then be installed across the total opening width. The same channel drainage system would likely be present at the driveway entrance along the property boundary to collect runoff from the property. Factors to consider would be channel depth, load rating and grate selection. When selecting a grate for a low traffic area that will be subjected to vehicles it is advisable to consider the likelihood of grate dishing and ongoing material finish (i.e. oxidisation in cast iron). Allproof’s Domestic Channel system is constructed from high grade plastic and is suitable for domestic vehicles by gaining its strength from the surrounding concrete. The Domestic Channel’s plastic grates appearance lasts and maintains shape under repeated wheel loads. If a higher load rating as per AS3996 is required in the situation where commercial vehicles or heavy loads such as boat trailers need to access the property, Allproof’s Polymer Concrete would provide an excellent alternative. Grade 316 stainless steel Wedge Wire (load class B or above) would make an excellent grate option in this situation.

Level Threshold Entry

At the main entrance to the dwelling a level threshold may be desired where the internal surface and external surface are not subjected to a level change, in this scenario E2/AS2 clause 7.3.2 applies. A 150mm deep by 200mm wide channel is required across the entrance with a grating system that will maintain a 12mm separation (drip line) from the joinery. A traditional 3 sided channel doesn’t work in this scenario as the joinery traditionally overhangs the building slab and will often vary in its width creating a narrower reveal in certain areas. Features to consider here would be the grate finish/material and slip resistance in accordance with AS4586. Allproof’s Perimeter Drain provides an off the shelf two sided channel solution for this with an adjustable Glass Filled Nylon (GFN) grate or a fully custom stainless steel grate supported by a bracket. The GFN grate has a matte black finish which compliments dark joinery and has an R10 slip rating whilst the 316 grade stainless steel Wedge Wire grate is made to measure by Allproof and offers an R11 slip rating. Allproof also offer a wide range of other fully custom manufactured systems to accommodate for a variety of other design variables, for more detailed information on designing the correct system and application for level threshold please see our article on How to Design E2 Compliant Level Access Building Entrances.

Sump/Collection Point

In a central or practical location a sump should be installed. This sump can be used to drain the surrounding surface area by creating falls towards it and therefore positioned accordingly, or it can be used as a collection point for the property’s other drainage systems. The sumps purpose is to provide suitable collection capacity for surface water from the surrounding area, provide sediment catchment while removing the likelihood of floatable solids entering the stormwater system and provide access for maintenance and cleaning. E1/AS1 states in clause 3.6.1 that “all surface water, except that collected directly from a roof, shall enter the drain via a sump which has:

-

-

- A grating, hinged or removable for maintenance access. The grating shall comprise at least 35% openings. The smaller dimension of any individual opening shall not exceed 35 mm,

- Capacity at the bottom for settlement of silt and debris, and

- A submerged (or trapped) outlet which prevents floatable solids entering the drain”

-

The channel systems previously highlighted all have outlet locations on the underside of each channel section, stormwater pipe would then drain the collected surface water away from the building and into the above sump. Allproof’s DP350x700RS has recently been brought to the market, the sump complies to the above E1/AS1 clause 3.6.1 with a round cast iron grate, 300mm of sediment collection and enough space above to include a half syphon outlet.

The Full System

Other drainage systems such as Allproofs Storm Series grates may also be required depending on the design of the property, these will follow a similar process and integration with the full system. A level of continuity can be achieved by selecting complementary systems from the same supplier, often grates and details are transferable between products allowing for an aesthetic language to be kept throughout the project.