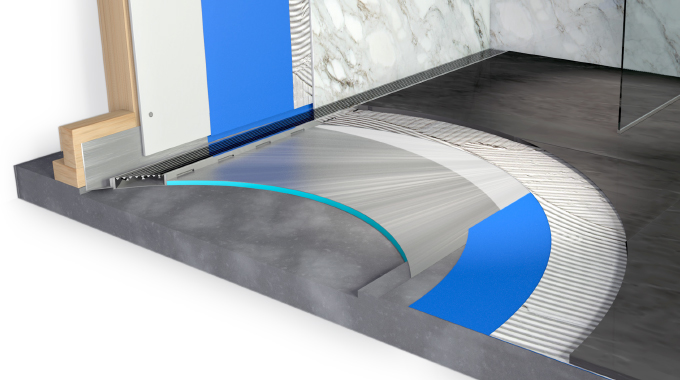

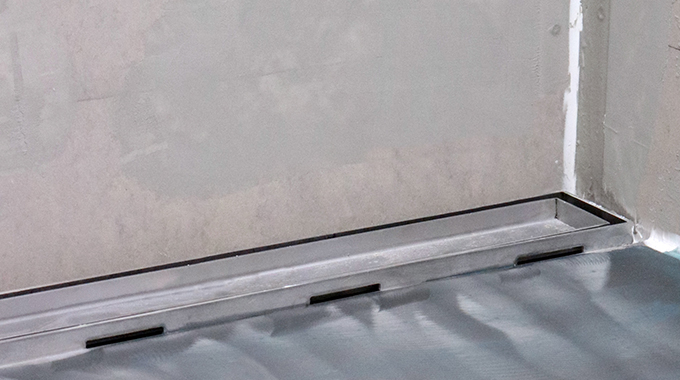

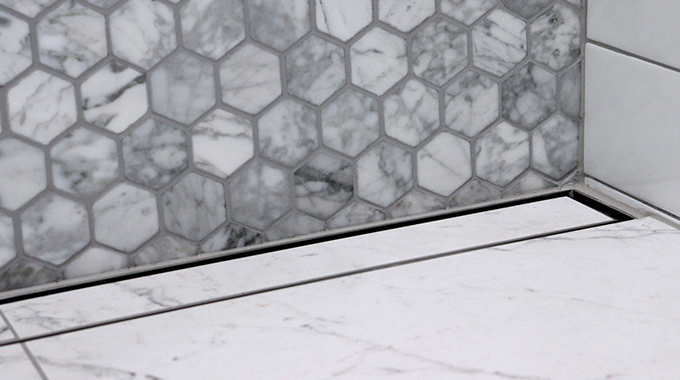

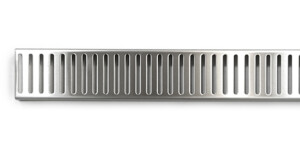

The Tile Over Stainless Shower Tray features a linear channel and grate for drainage, placed at the lowest end of the fall to ensure proper water flow. It includes a tile bar with sub-tile drainage paths to prevent tile damage from moisture. Allproof’s Vision shower channels are available, offering 5 stylish grate options including a discreet Tile Insert option.

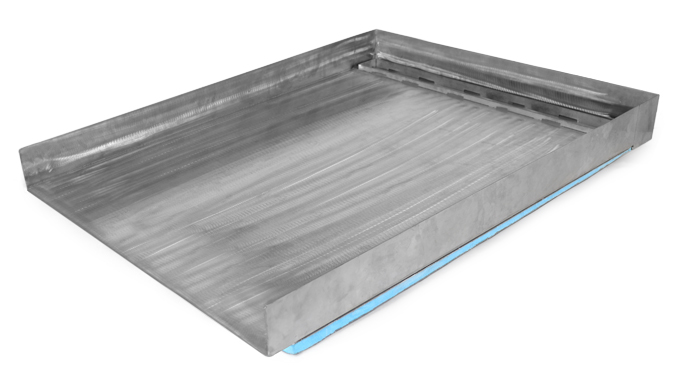

Shower Tray-Tile Over Stainless

Shower Tray-Tile Over Stainless

NZ Made Stainless Steel Shower Trays

The Tile Over Stainless Steel shower tray provides the ultimate waterproofing system for tiled showers and wetrooms. The stainless steel provides an impermeable layer beneath the tiles under the shower, the area of the bathroom that is exposed to the highest level of moisture.

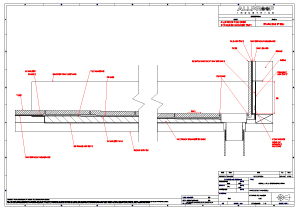

This unique shower base is custom-made from 304 and 316 stainless steel to suit each shower. The shower tray comes with an engineered XPS base pre-fixed to the underside of the stainless tray creating a 1:80 fall for hob entry showers or a 1:50 fall for level entry showers, this removes the need for screeding a fall into the tray reducing install time and costs. A waterproof membrane is dressed down the walls and across the rest of the bathroom floor to be applied to the textured stainless steel flanges creating a fully tanked / waterproofed area.

Tile over stainless shower trays are recommended in showers on levels above living spaces as well as in timber framed and intertenancy builds. The tile over stainless shower base provides peace of mind and assurance that water is unable to escape causing damage and inconvenience.

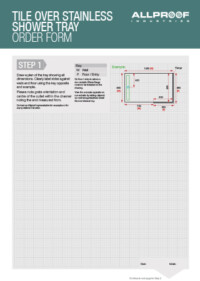

Allproof specialises in the design and production of custom stainless shower trays and bases with a large team of product designers and fabricators ready to tailor a shower tray to your next project. Custom quote sheets are available from the custom tab below.

Features:

- Custom-made from 304 or 316 stainless steel

- Supplied with engineered XPS base to create built-in falls:

– 1:80 fall for hob entry

– 1:50 fall for level entry - No screeding required – faster, easier installation

- Textured flanges for membrane adhesion, forming a full tanking system

- Ideal for timber-framed and multi-level builds

- Eliminates risk of water damage from leakage

- Designed and manufactured in New Zealand

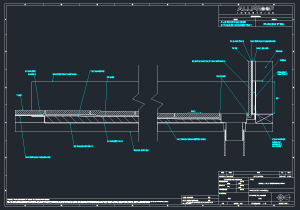

Install Drawings

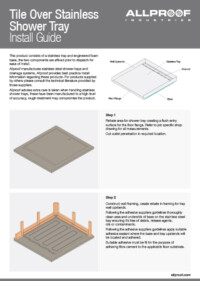

Install Guide

Design Notes

Maximum tray dimensions are 2800mm x 1300mm.

Due to production limitations a true level entry can only be achieved on a tray with 3 wall upstands and the channel/outlet directly opposite the entry side (fall directed away from the entrance to the channel). For level entry applications with less than 3 wall upstands, a minimum 10mm step down is required at the entry of the tray (a recommended feature for the containment of surface water).