Allproof’s 100% Recycled Channel Drain ‘Closes the Loop’

Pact Group processes and supplies high quality locally recycled material. “Completely closing the loop, guarantees consistent supply and integration of food-grade and non-food grade recycled local resin across all industry sectors.” – pactgroup.com

Pact Group have recently upgraded their hard plastics wash line which cleans and fragments a range of plastic materials. Pact Group process around 1000 tonnes of recycled Polypropylene (PP) resin per year, the upgraded wash line provides the ability to increase this. The material comes from various streams such as post-consumer.

Roadside recycling is collected, sorted and bundled at an Auckland Material Recovery Facility (MRF). Pact Group purchase bundles of PP from this facility to be processed back into 100% recycled material. This is then supplied to Allproof to manufacture a range of drainage and passive fire protection products, such as the Commercial Channel drain range. The whole process, from recycle bin to new product, takes place in Auckland.

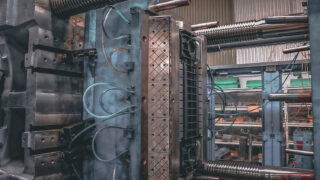

The upgraded wash line facility uses large volumes of water for the cleaning process, this water is recycled on site to reduce usage. With any commercial activity involving water a reliable and high performing drainage system is essential. The drainage system must be able to accommodate for any spills to remove hazards and efficiently remove large volumes of water in the unlikely event of an equipment malfunction.

Allproof’s 200mm clear opening Commercial Channel was selected as the drainage solution. A total of 63 metres of channel has been installed around the internal perimeter of the facility. At the entrance, 10 metres of the Heelproof Cast Iron (HCI) grate were installed to accommodate forklifts carrying bales of recycling in, and then transferring bags of cleaned and ‘chipped’ material out to the next facility to complete the process. The HCI grate has a Class D load rating (AS3996) and P5 slip resistance (AS4586) providing the ideal solution for high traffic and heavy commercial applications exposed to wet conditions.

The Glass Filled Polypropylene (GFP) grate was selected for the drainage channels around the rest of the facility where only class A pedestrian traffic occurs. This grate also has a P5 slip resistance, reducing workplace risk, an important consideration for Pact Group, who state “safety is first” among their corporate values.

Both the channel and GFP grate are manufactured at Allproof’s bronze enviromark® certified facility using solar energy and 100% recycled PP processed in the facility where the product is now installed. This closes the loop, delivering a high performing, sustainable drainage solution through the collaboration of two innovation-driven companies.